| Feature 1: Automatic leveling | |

Thefirst scanner with automatic leveling function 1. Powerful! Suitable for upright and inverted Accuracy 3" when the instrument is tilted <±5° Accuracy ≈10” when the instrument is tilted> ±5°, <±45° 2. The elevation accuracy at 80 meters reaches 1mm 3. In the default mode, the scanner will be leveled automatically: time-saving and error-proof 4. The instrument checks the leveling status in real time, and automatically stops scanning if the threshold is exceeded 5. After scanning at each station, the instrument will check the leveling status and report an error Automatic leveling saves time for field data collection and truly realizes one-key operation; it is very friendly to non-professionals; it reduces the time of exposure to complex and dangerous environments and ensures personnel safety; high-precision leveling results and The wide-angle leveling range allows you to set up stations at any location, effectively ensuring data security. Moreover, the automatic leveling expands the scope of application of the scanner. Now, you can put the scanner on a trolley, bicycle, or car, and you can build your own mobile scanning system without having to buy an expensive automatic leveling base. |  |

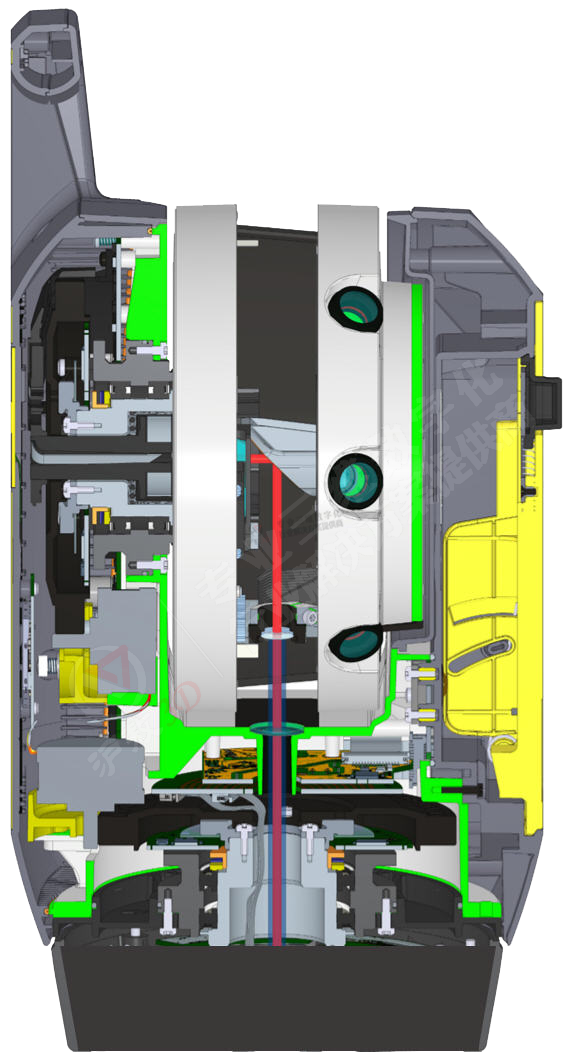

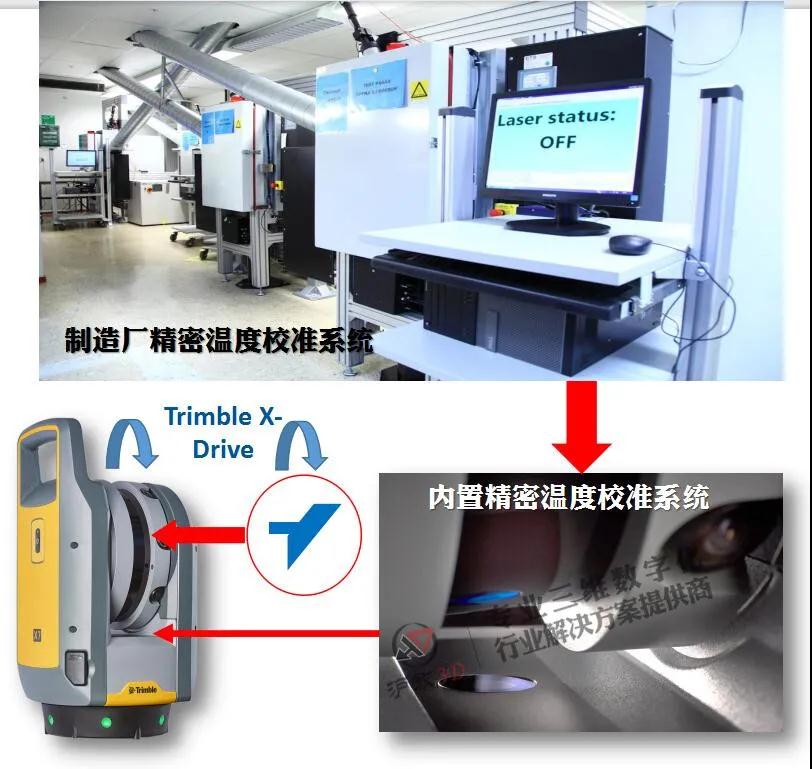

| Feature 2: Automatic calibration | |

The first optical instrument with automatic calibration General scanners usually need to be returned to the factory for maintenance and calibration once a year in a special laboratory to ensure the accuracy of the scanner's laser head. The Trimble X7 3D scanner has an automatic calibration function. There is no need to return to the factory, let alone a special inspection site and professional technicians. The instrument can automatically calibrate immediately. At the same time, Trimble's automatic calibration function is extremely intelligent, it will detect the environmental temperature, light, vibration, instrument temperature and vertical speed of various influencing factors, in order to comprehensively optimize the calibration process. Under normal conditions, fully automatic calibration takes about 25 seconds, and under the worst conditions, the process will automatically adapt to 45 seconds to ensure accurate and reliable results. Automatic calibration can effectively compensate for the error caused by temperature difference, and after the temperature is stabilized, the calibration time will be greatly shortened or even no longer needed. Automatic calibration can also calibrate the deviation caused by shock and vibration during transportation. When working, automatic calibration continuously monitors the internal and external conditions of the instrument, and performs calibration refresh when necessary to keep the results within the accuracy range.

| |

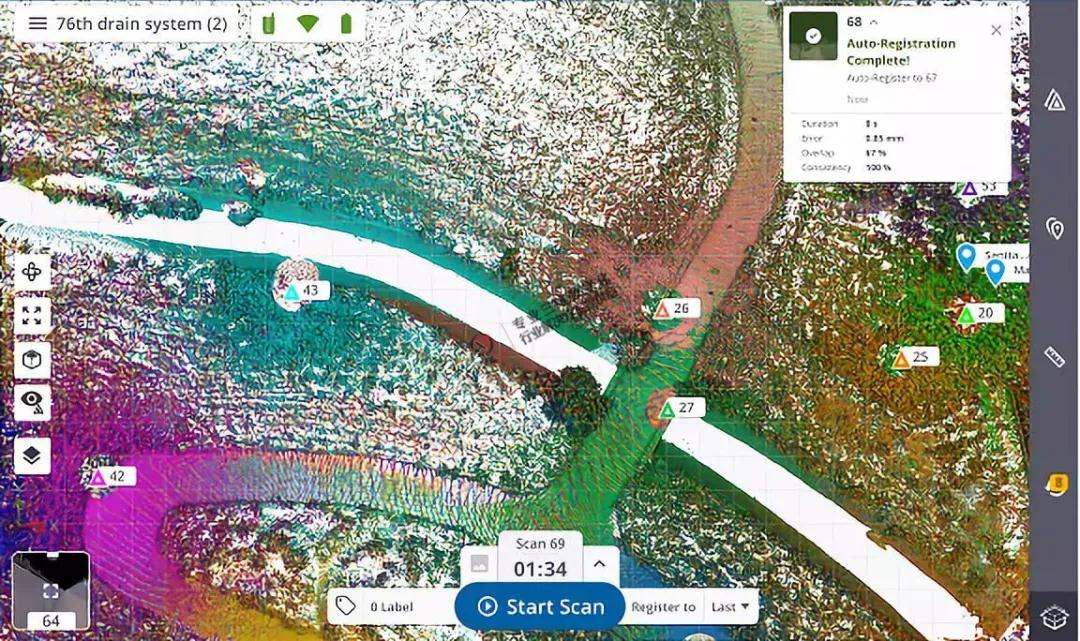

| Feature 3: On-site real-time, automatic, high-precision registration | |

The first scanner to achieve true automatic registration in the field Trimble X7 has a built-in high-precision inertial navigation module, which can track every position change of the scanner. While scanning, it completes automatic targetless registration and point cloud coloring. The system refines the point cloud registration, and the detailed registration report contains station error and consistency check results. The goalless automatic registration in the field helps us to improve our work efficiency by another level. We don't have to go back to the office to process data; we don't have to use high-performance computers and wait a long time for point cloud registration and coloring. After scanning, you can immediately use the point cloud for 3D modeling, drawing, earthwork calculation and other tasks, which truly realizes the instant scan and use, the overall quality report can be obtained on the spot, and the results can be submitted on the spot. | |

|  |

| |

| Feature 4: Laser pointer | |

The first 3D scanner with a laser pointer

| |

| |

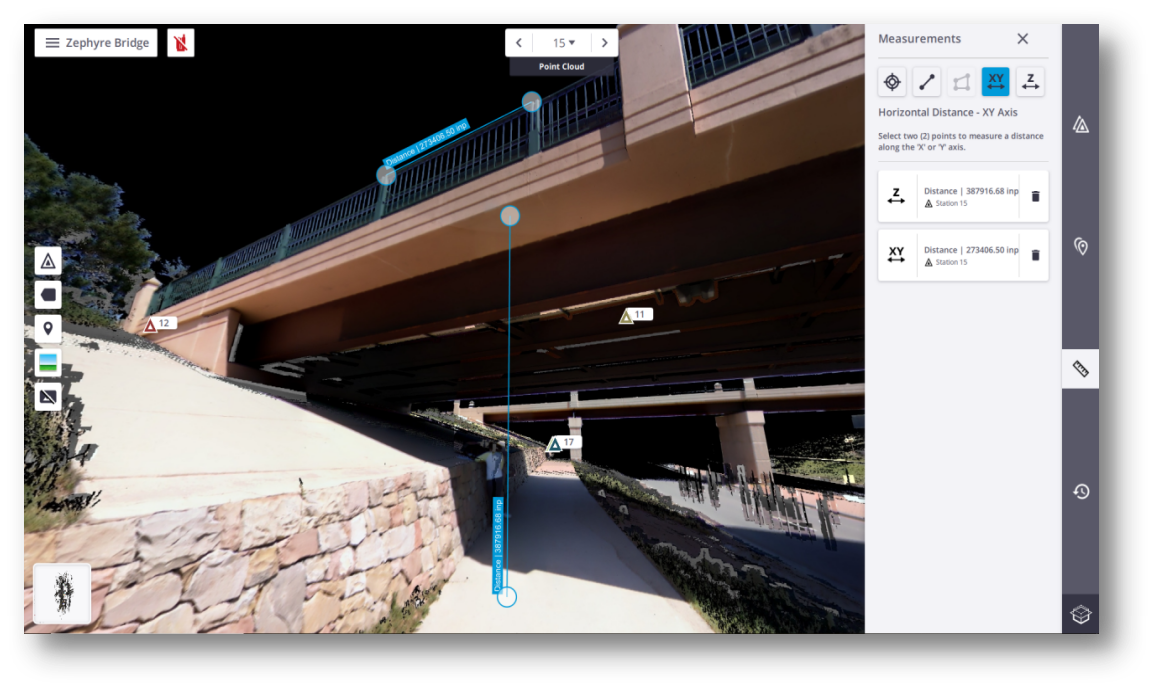

| Feature 5: Label and annotation function | |

| |

| |

| Feature 6: Scan now and test now | |

| |

| |

| Feature 7: 360 high-speed panoramic photography | |

| |

| |

| Feature 8: High sensitivity mode-for difficult surfaces | |

Accuracy consistent with standard mode for difficult surfaces Dark difficult surface: black, asphalt pavement, coal Difficult reflective surfaces: stainless steel, bright metal, glass, wet ground | |

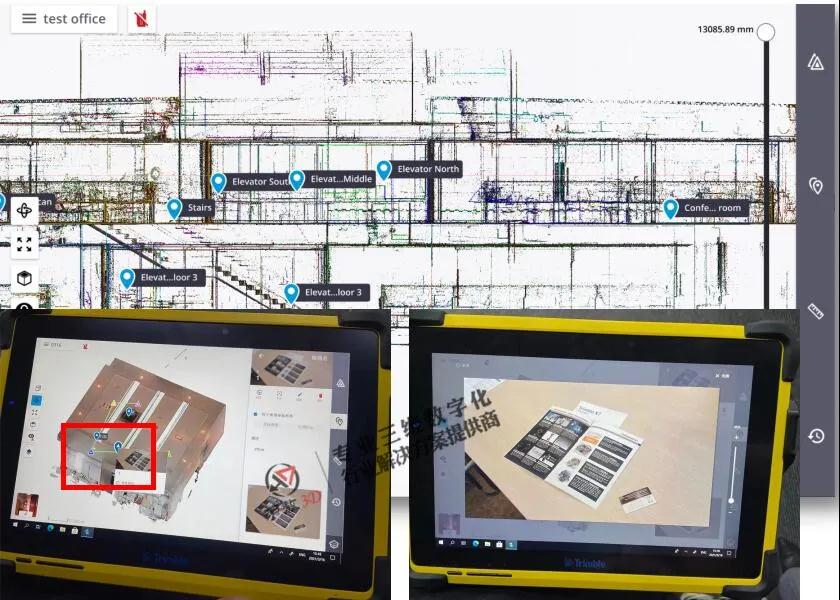

| Feature 9: Equipped with a military standard tablet computer

| |

| |

| |

Feature 10: Adapt to difficult conditions | |

|  |

| Feature 11: Reliability of equipment | |

| |

| |

| |